About Thermal Fluid Hot Oil Heater with Cooling Unit

Product Description

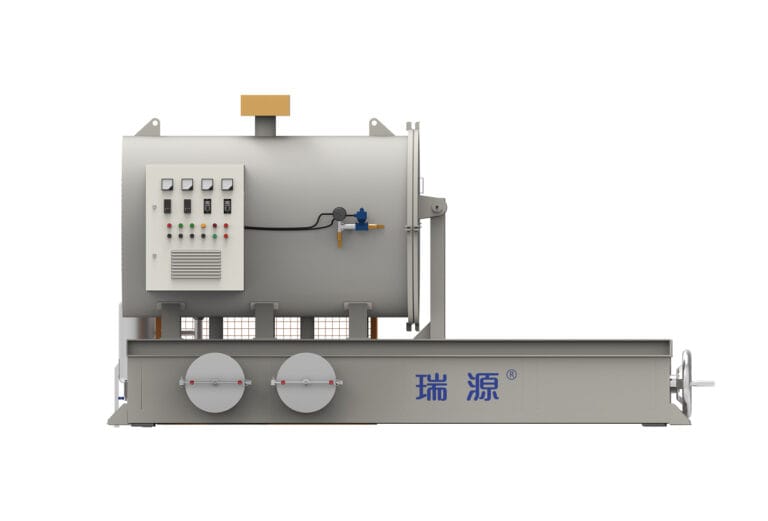

Thermal Fluid Hot Oil Heater with Cooling Unit is designed for process temperature control up to 350℃, which is custom designed for each application, using synthetic heat transfer fluids. TOH series thermal oil heater is the most compact temperature control system. The system include an electric heater, centrifugal pump, expansion tank, control panel, strainer, stop valves, platinum resistance thermometer sensor, pressure gauge with electric contact, alumina silicate fibre insulation and connecting piping mounted in a welded steel frame.

Normally a pump transports the thermal oil into the heater, which is then heated. The thermal oil will then flow out of the heater at a fixed flow rate decided. The heat generated is evenly distributed and the efficiency of the heater is high. Temperature sensors can be used with control to achieve the desired temperature range.

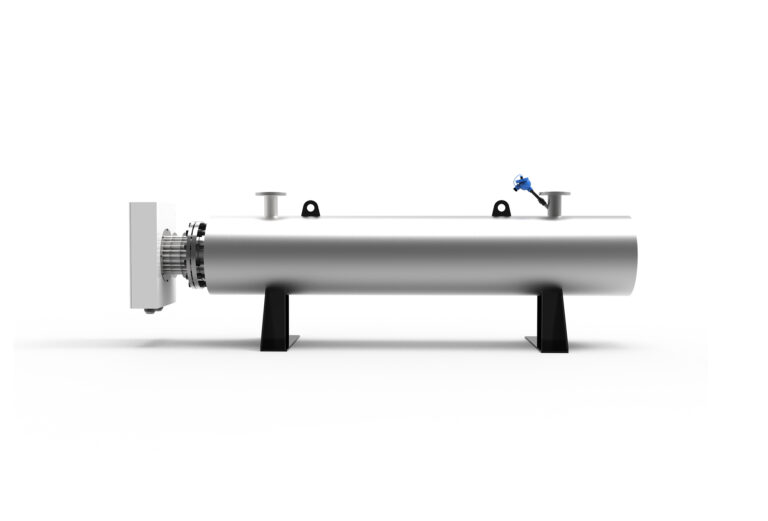

The heater could come with a shell and tube cooling exchanger and a three way diverting valve for processes that require heating and cooling.

APPLICATIONS

- Reactor, Distillation still, etc.

- Evaporator

- Heat Press

- Roller

- Mold

- Exchanger

- Oven

- Dryer

- Tank (Asphalt tank, Grease tank, etc.)

FEATURES

- All welded construction

- Thermal insulation provided to prevent heat loss

- Low pressure and high temperature

- Isolation gate valves and strainer

- Terminal enclosures available for easy wiring

- Functional test of system prior to shipment

- Highly customizable to meet specifications

CONTROL

- Digital PID temperature controller

- SSR or SCR power controllers

- Brand electrical components (Siemens, Omron, Schneider Electric, ABB, etc.)

- Heat ON/OFF switch

- Audible and visible alarm indicators

- Control Accuracy: ±1°C

- 3∼3000KW input power supply to your specifications

- Temperature recorder (optional)

- PLC with HMI(touch panel) (optional)

- RS485 communication protocols (optional)

- Programmable temperature controllers (optional)

SPECIFICATIONS

SCHEMATIC DIAGRAM

PIPE CONNECTION DIAGRAM

).jpg)